5HHS-30M型低溫谷物干燥機

5HHS-30Mtype low temperature grain dryer

上下無絞龍混流式干燥,高效率、360度無死角烘干技術:

5HHS-30M型干燥機的干燥箱采用不銹鋼(選配)角管交叉導流,采用負壓低溫干燥技術,多級混流烘干與緩速相結合的烘干工藝,相比傳統烘干機提高烘干效率30%;獨特的角管混流式烘干技術保證您的糧食在烘干時全方位360度無死角,保證谷物烘干后的水分均勻性,獨特的上下無絞龍和底部出料設計,破碎率更低,出糧速度更快,在線水分儀實時監測谷物含水量,烘干谷物達到用戶設定的水分值后自動停機。

整機鈑金厚板配置,使用壽命長:

干燥機整機箱體鈑金零部件采用厚度≥1.5的優質碳合金鋼板,干燥箱內部角管采用優質碳合金不銹鋼材質(選配),使干燥機經久耐用,使用壽命長。

特大烘干層,提高烘干效率,降低烘干成本:

國內先進排糧結構設計,一機多用設計。可干燥水稻、小麥、玉米、油菜籽、大豆等顆粒狀谷物;干燥速度快,3.5M*2.5M*2.4M特大干燥層,采用不銹鋼角管式混流干燥(選配),干燥性能大幅度提升,烘干均勻且效率高。

智能控制,安全可靠,烘干過程全程無憂:

整機設備自動化程度高,觸摸屏操控界面,操作簡單方便,控制系統融合工業4.0設計,互聯網+時代的新型智能控制系統(選配),全程自動化控制,并且能給您提供快速,高效,精準的售后服務,設備故障報警,滿糧報警,熱繼電器,熱風溫度傳感器,設計全方位安全裝置,防過載等安全裝置,安全可靠。

High efficiency and 360° no dead angle drying technology:

5HHS-30M dryer drying box using stainless steel (optional) corner tube cross flow, using negative pressure low temperature drying technology, multi-stage mixed flow drying and slow combined drying process, compared with the traditional dryer to improve drying efficiency 30%; Unique Angle of tube mixed flow drying technology to ensure your full 360 degrees when drying grain no dead Angle, ensure the grain drying moisture uniformity, unique design without ground dragon and bottom discharging from top to bottom, broken rate is lower, the food faster, real-time monitoring of online moisture meter, grain moisture content, drying grain reach moisture value set out by the user automatic stop.

Whole machine sheet metal is thick plate,long service life:

The outer sheet metal of the dryer is high quality carbon alloy steel plate with thickness of more than2mm. The inner angle pipes of the drying cabinet are made of high quality carbon alloy stainless steel, which makes the dryer durable and have long service life.

Super drying cabinet can make drying process with high efficiency and at low cost:

Domestic advanced grain dryer discharging structure design can suitable for many varieties of grain, such as rice, wheat, corn, rapeseed, soybean and so on:The drying speed is fast, the3.5M*2.5M*2.4M super drying cabinet is made of stainless steel angle pipes mixed flow drying, which makes drying speed fast, the drying performance is greatly improved, also make the drying process with the high efficiency.

Intelligent control make machine running safe and reliable:

The whole machine has high automation, touch-screen control interface, simple reliability and easy operate a tion, electric cabinet on equipment with industrial 4.0 intelligent control system, we can accurate position. ing problems in the background of the equipment so that it can response after-sales intelligently, here is the new mode of after-sales service internet age, this design will provide after-sales service for you effec. tively and accurately. There is a complete set of safety control systems on the equipment including malfur、tion alarm, full grain alarm, hot relay, hot air temperature sensor, overload protection and other safety. devices to make the running process of the equipment can run safely and steadily.

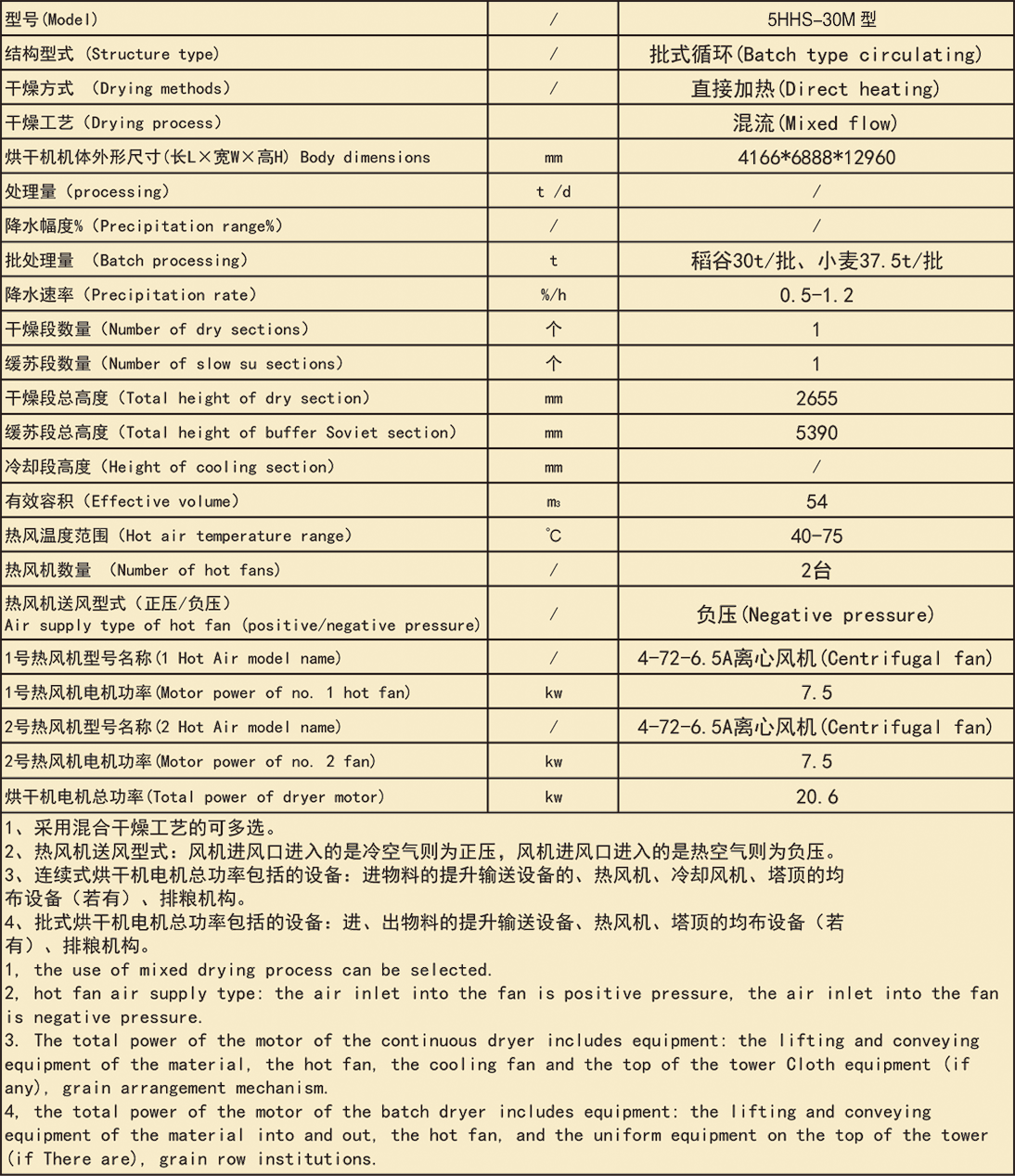

5HHS-30M型低溫谷物干燥機——技術參數

備注:

1、本表所列之性能及降水率為參考數值,稻谷水份是由28%烘至15%;小麥是由30%烘至14%為止的數值,實際數值會因外氣溫度、相對濕度、干燥品種、熱風溫度、進風溫度、熱源類型和品質及干前、干后含水率而有所差異。

2、上表中的數據僅供參考,因產品技術不斷改進,本公司更改后恕不另行通知。

1、 he performance and precipitation rate listed in this table are reference values, the water content of rice is reduced from 28%. to 15%, and the value of wheatis from 30%to 14%. The actual value vary according to external gas temperature, relative humility. dry variety, hot air temperature, inlettemperature, type and quality of heat source, and moisture content before and aterdy.

2、Specification is subject to change without prior notice.

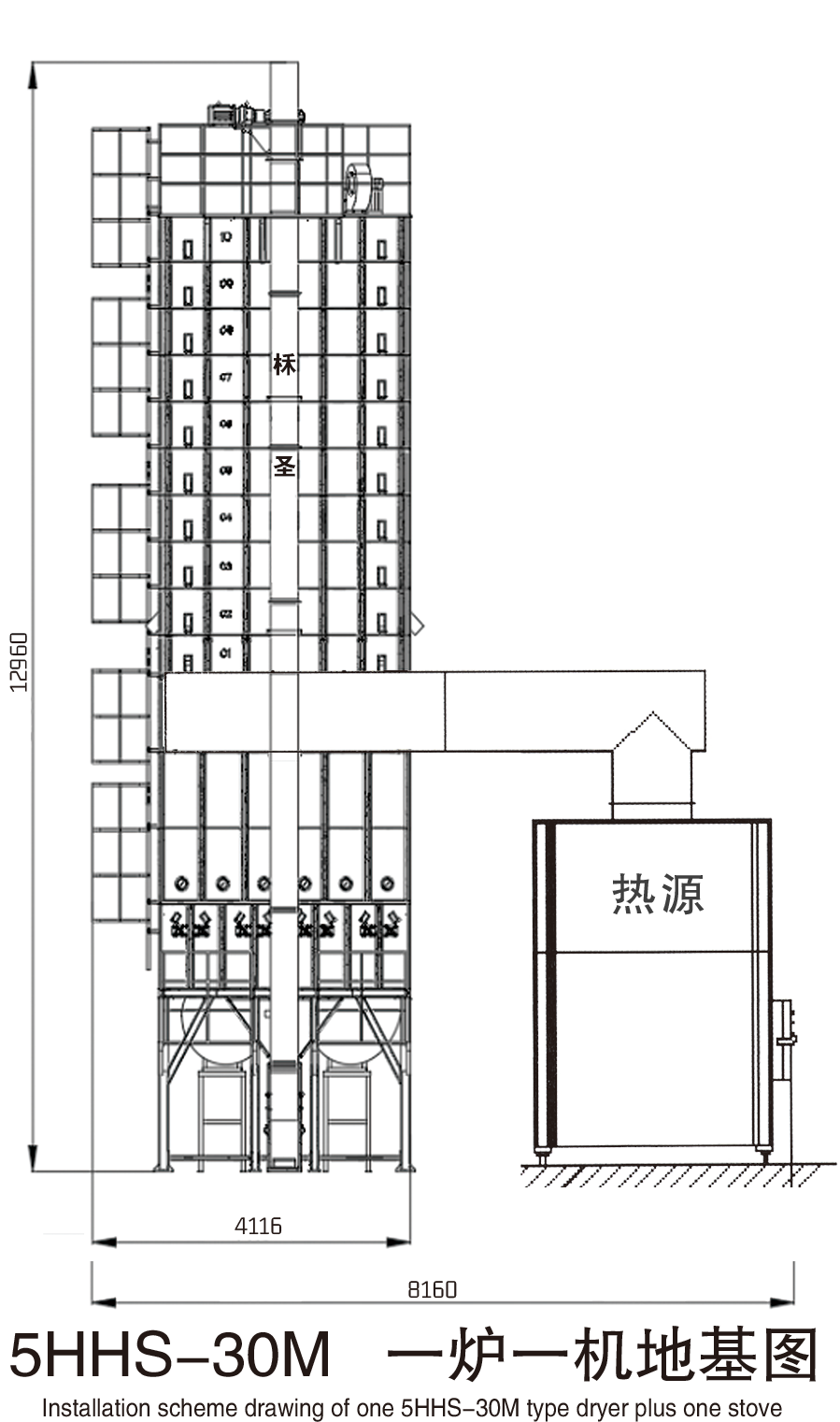

5HHS-30M型低溫谷物干燥機——標準配置地基圖

單位 (mm) Unit (mm)

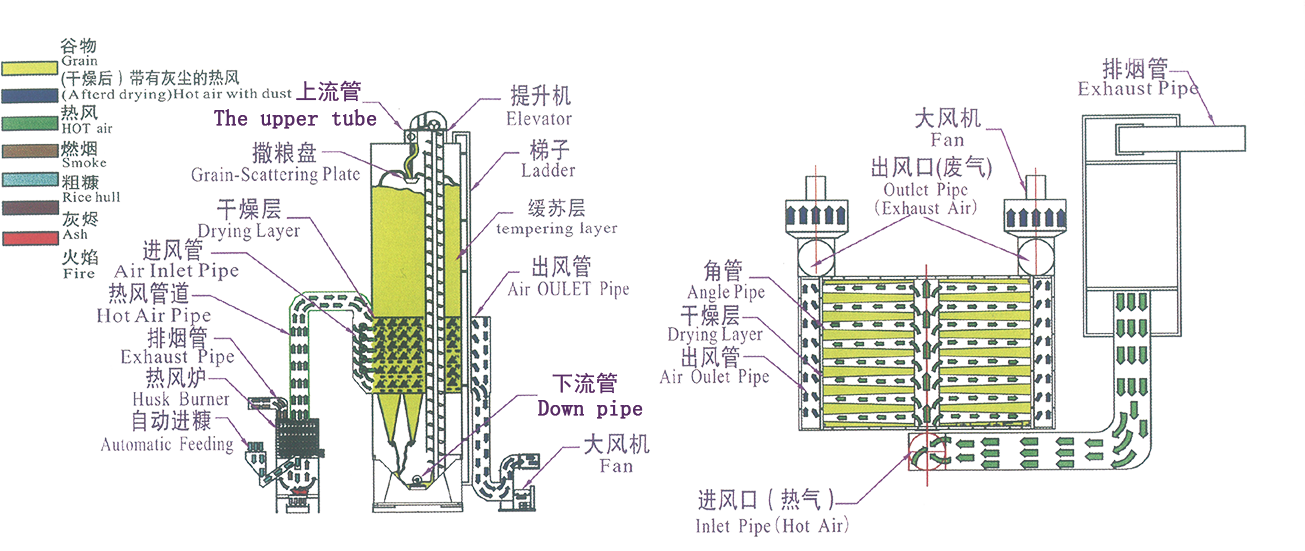

5HHS-30M型低溫谷物干燥機——原理圖

The schematic diagram of 5HHS-30Mtype grain dryer

工作原理

單個批次谷物進入干燥機后,通過電器件的相互配合運行使得谷物在干燥機中進行有序循環,再由熱風爐燃燒燃料產生熱風,在單臺電動風機的作用下,讓熱風通過混流式干燥層的風道,穿透和功加熱谷物,通過空氣流動帶走谷物中的水分,帶有水分的廢氣經過風機的吸力通過管道排出機外,干燥的谷物經過自動在線水分儀檢測達到預先設置的水分點后,停機,干燥完成。

Working principle

After a single batch of grain into the drying machine, use the electric parts together running makes grain an orderly circulation in the dryer, again by hot blast stove burning fuel to produce hot air, under the action of a single electric fan, let air by mixed flow drying layer of air duct, penetration and heating grain work, take away moisture from the grain through air flow, The exhaust gas with moisture is discharged from the machine through the suction of the fan through the pipe, and the dry grain is detected by the automatic online moisture meter to reach the preset moisture point, then the machine is stopped and the drying is completed.

上一篇:燃油燃氣燃燒室